::how big an a4 paper is.

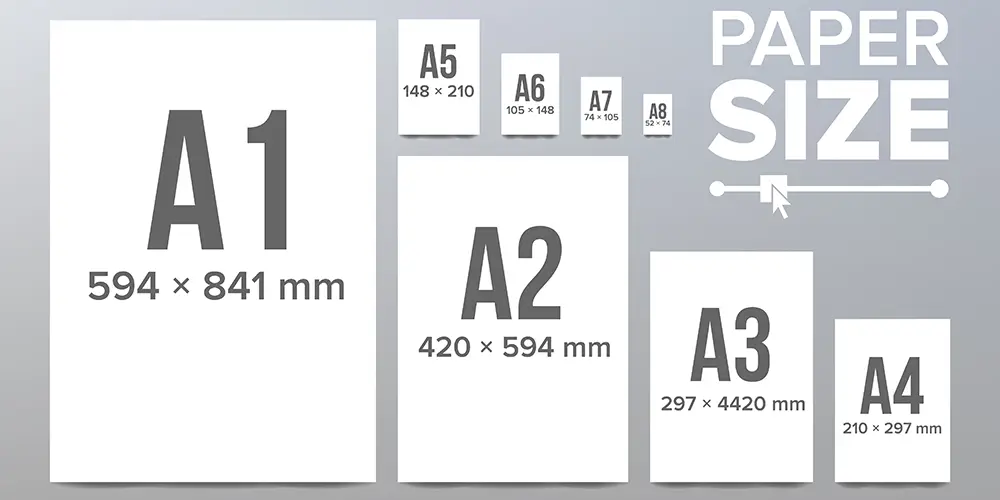

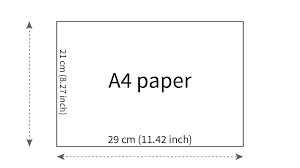

A4 paper’s measures 210 millimeters (mm) by 297 millimeters (mm), which is approximately 8.27 inches by 11.69 inches. It is part of the ISO 216 standard, which is widely used internationally. A4 paper is commonly used for letters, printing, and office documents.

::how long are a4 paper‘s?

The length is 297 millimeters (mm), or approximately 11.69 inches. This is the longer side of the A4 sheet in portrait orientation.

::how much a4 paper weights.

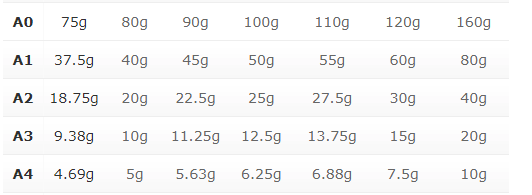

The weight of A4 paper depends on its grammage, which is measured in grams per square meter (gsm). The most common A4 paper weights are:

- 80 gsm: Standard office paper used for printing and copying.

- 90-100 gsm: Slightly heavier paper often used for letters or documents.

- 120-160 gsm: Heavier paper used for high-quality presentations, flyers, or brochures.

- 200-300 gsm: Cardstock used for covers, invitations, or business cards.

To find the weight of an individual A4 sheet, you can use this formula:

Weight of A4 sheet (g)=Grammage (gsm)×Area of A4 sheet (m2)1\text{Weight of A4 sheet (g)} = \frac{\text{Grammage (gsm)} \times \text{Area of A4 sheet (m}^2\text{)}}{1}Weight of A4 sheet (g)=1Grammage (gsm)×Area of A4 sheet (m2)

For example, for 80 gsm paper:

- A4 area = 0.21×0.297=0.06237 m20.21 \times 0.297 = 0.06237 \text{ m}^20.21×0.297=0.06237 m2

- Weight of one A4 sheet = 80×0.06237=4.9896 grams80 \times 0.06237 = 4.9896 \text{ grams}80×0.06237=4.9896 grams

So, a single sheet of 80 gsm A4 paper weighs approximately 5 grams.

how a4 paper is made…..

The process of making A4 paper involves several stages, from raw material preparation to the final cutting into A4 sheets. Here’s an overview of the paper-making process:

1. Raw Material Preparation

- Wood Pulp: Most paper is made from wood pulp, derived from softwood (e.g., pine) or hardwood (e.g., eucalyptus) trees.

- Recycled Paper: Recycled fibers from used paper can also be used.

- Pulping: The raw materials are turned into pulp by mechanical or chemical processes:

- Mechanical Pulping: Wood is ground down.

- Chemical Pulping: Chemicals break down lignin (a substance that binds wood fibers), leaving cellulose fibers.

2. Pulp Processing

- Bleaching: The pulp is bleached to achieve the desired whiteness and remove any remaining impurities.

- Refining: The pulp is refined to improve the strength and quality of the paper.

3. Papermaking

- Sheet Formation: The refined pulp is diluted with water and spread onto a moving mesh screen (the “Fourdrinier machine”).

- Water Removal: Water is drained from the pulp, leaving a mat of fibers. This mat is then pressed to remove more water.

- Drying: The paper is dried using heated rollers to achieve the desired moisture content.

4. Finishing

- Calendering: The dried paper passes through calendering rollers to smooth and flatten it, giving the paper its finished texture.

- Coating (Optional): A coating may be applied for glossy or matte finishes, depending on the intended use.

5. Cutting

- Reeling: The finished paper is wound onto large reels.

- Cutting to Size: The paper is cut into sheets of various sizes, including A4 (21 cm by 29.7 cm).

6. Packaging

- The A4 sheets are packaged into reams, typically containing 500 sheets, and then distributed for use in offices, schools, and homes.

This process results in the A4 paper used worldwide for printing, writing, and various other applications.